Hybrid-electric propulsion systems

define new ways of air transport

PRODUCTS

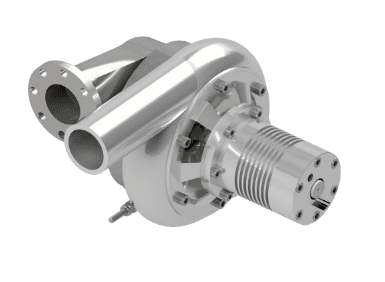

TURBOGENERATOR

Self-contained system includes gas turbine engine, generator, heat exchanger, drive, inverter, and thermal management using air cooling.

MOTOR INVERTOR

Sensorless control from 15 krpm up to 160 krpm, Inverter for driving high speed permanent magnet motors.